Wastewater

Recovery

For Food, Beverage, Agriculture and Wine

Wastewater

Recovery

For Food, Beverage, Agriculture and Wine

Wastewater

Recovery

For Food, Beverage, Agriculture

and Wine

Experts who design and provide you water scarcity solutions

We are water recycling experts who solve water uncertainty with proven technologies. Our water recovery plan combines reuse and recycling to improve your water security. We use our 20 years of experience in liquid filtration to construct and provide the custom hardware and process schemes that would work best for your facility to solve the toughest water issues.

California Statewide General Waste Discharge Requirements winery presentation

Change in water availability limiting your growth?

Concern over reductions in water availability?

The drought in California is ongoing.

Troubled about increased water disposal surcharges?

Regulations are increasing wastewater disposal difficulties.

Changes in regulatory agenda in water affecting growth?

Approvals for new wells are almost impossible in Sonoma County.

Scarce Land being used consumed by wastewater ponds and water application areas?

You have better uses for highly valuable real estate.

California Statewide General Waste Discharge Requirements winery presentation

Change in water availability limiting your growth?

Concern over reductions in water availability?

The drought in California is ongoing.

Troubled about increased water disposal surcharges?

Regulations are increasing wastewater disposal difficulties.

Changes in regulatory agenda in water affecting growth?

Approvals for new wells are almost impossible in Sonoma County.

Scarce Land being used consumed by wastewater ponds and water application areas?

You have better uses for highly valuable real estate.

Water availability

will not limit

your future?

Threats from scarcity on the supply side along with new regulations on disposal side have the potential to check your growth or limit your production. The answer is recycling through advanced filtration technologies. Recovered Water Solutions, water recycling experts, will provide you with new technical solutions that efficiently reuse your valuable water resources. We are experienced filtration providers. Our water recycling experts will work with you on water reuse solutions to protect your operation from the coming impacts in water availability and disposal costs.

Water availability will not limit your future?

Threats from scarcity on the supply side along with new regulations on disposal side have the potential to check your growth or limit your production. The answer is recycling through advanced filtration technologies. Recovered Water Solutions, water recycling experts, will provide you with new technical solutions that efficiently reuse your valuable water resources. We are experienced filtration providers. Our water recycling experts will work with you on water reuse solutions to protect your operation from the coming impacts in water availability and disposal costs.

Our water recycling experts

will insure your success.

We are water recycling experts with 20 years of expertise in critical filtration! We can solve your water security challenges.

- 20 years experience with targeted filtration technologies.

- 7 year history of constructing skid-mounted filtration systems.

- 35 plus years of combined Chemical Engineering experience with focus on water filtration

- Veolia Water Technologies & Solutions (GE Water & Process Technologies and Suez Water Technologies) partnership, the industry leader in wastewater recycling and recovery.

Solve your water issues today!

TRUSTED PARTNERSHIPS WITH INDUSTRY LEADERS

Our water recycling experts will insure your success.

We are water recycling experts with 20 years of expertise in critical filtration! We can solve your water security challenges.

- 20 years experience with targeted filtration technologies.

- 7 year history of constructing skid-mounted filtration systems.

- 35 plus years of combined Chemical Engineering experience with focus on water filtration

- Veolia Water Technologies & Solutions (GE Water & Process Technologies and Suez Water Technologies) partnership, the industry leader in wastewater recycling and recovery.

Solve your water issues today!

TRUSTED PARTNERSHIPS WITH INDUSTRY LEADERS

We can customize a solution to your facilities

wastewater challenges

Call us to provide a water risk assessment tailored specific to your facility’s wastewater challenges. We will use it to meet your goals. Our water recovery systems will integrate with your current infrastructure to recycle your wastewater and even achieve zero liquid discharge (ZLD)!

We can customize a solution to your facilities

wastewater challenges

Call us to provide a water risk assessment tailored specific to your facility’s wastewater challenges. We will use it to meet your goals. Our water recovery systems will integrate with your current infrastructure to recycle your wastewater and even achieve zero liquid discharge (ZLD)!

Easy Steps to Water Security

Water Risk Assessment

On-site and engineer review of your water uses and wastewater system

Water Recovery Plan

Equipment recommendations, treatment trial & cost engineering

Solutions Delivered

Permitting Support, Engineered Solution & Supply

Includes start up and continuing

technical support

Easy Steps to Water Security

Water Risk Assessment

On-site and engineer review of your water uses and wastewater system

Water Recovery Plan

Equipment recommendations, treatment trial & cost engineering

Solutions Delivered

Permitting Support, Engineered Solution & Supply

Includes start up and continuing

technical support

Easy Steps to Water Security

Water Risk Assessment

On-site and engineer review of your water uses and wastewater system

Water Recovery Plan

Equipment recommendations, treatment trial & cost engineering

Solutions Delivered

Permitting Support, Engineered Solution & Supply

Includes start up and continuing

technical support

RWS will guide you through wastewater recycling and towards greater water security

- Minimize your cost of doing business in a water scarce environment

- Customize solutions to meet your water needs

- Provide access to the industry’s top water experts

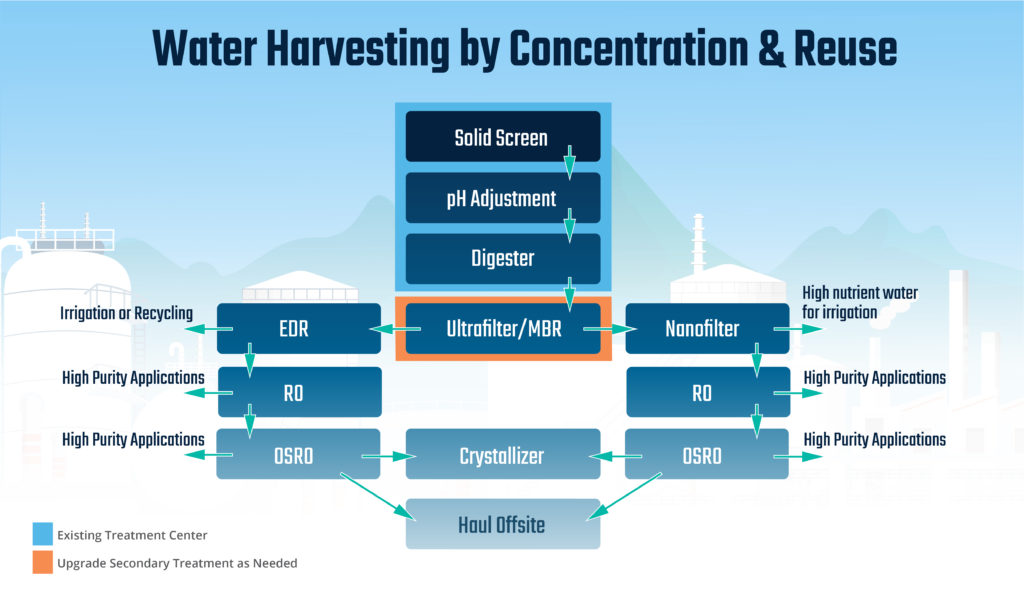

What does winery water recovery look like?

Each winery has their own method to manage their grapes from their appellation to create an integrated result. The same may be said for water. Every facility’s feed water and process are unique, so a degree of customization is required to optimize your system. In addition, the most valuable use of the recovered water and local regulatory issues will drive the final design of your Resource Recovery Units.

We will provide you with a process that fits your process to create an integrated, optimal program to create usable water. We will use staged filtration to refine water into a recoverable product. We will deploy combinations of electrodialysis and reverse osmosis as well as de-ionization, precipitation or membrane softening steps required to create a customized Resource Recovery Unit for your facility. We will help you determine how much water is ideal to recover. We even offer technologies that are capable of eliminating liquid waste completely. We will help you decide the proper balance of benefit and cost.

RWS will guide you through wastewater recycling and towards greater water security

- Minimize your cost of doing business in a water scarce environment

- Customize solutions to meet your water needs

- Provide access to the industry’s top water experts

What does winery water recovery look like?

Each winery has their own method to manage their grapes from their appellation to create an integrated result. The same may be said for water. Every facility’s feed water and process are unique, so a degree of customization is required to optimize your system. In addition, the most valuable use of the recovered water and local regulatory issues will drive the final design of your Resource Recovery Units.

We will provide you with a process that fits your process to create an integrated, optimal program to create usable water. We will use staged filtration to refine water into a recoverable product. We will deploy combinations of electrodialysis and reverse osmosis as well as de-ionization, precipitation or membrane softening steps required to create a customized Resource Recovery Unit for your facility. We will help you determine how much water is ideal to recover. We even offer technologies that are capable of eliminating liquid waste completely. We will help you decide the proper balance of benefit and cost.