Water Recovery Technology

How We Can Help With Your Commercial Wastewater Recycling

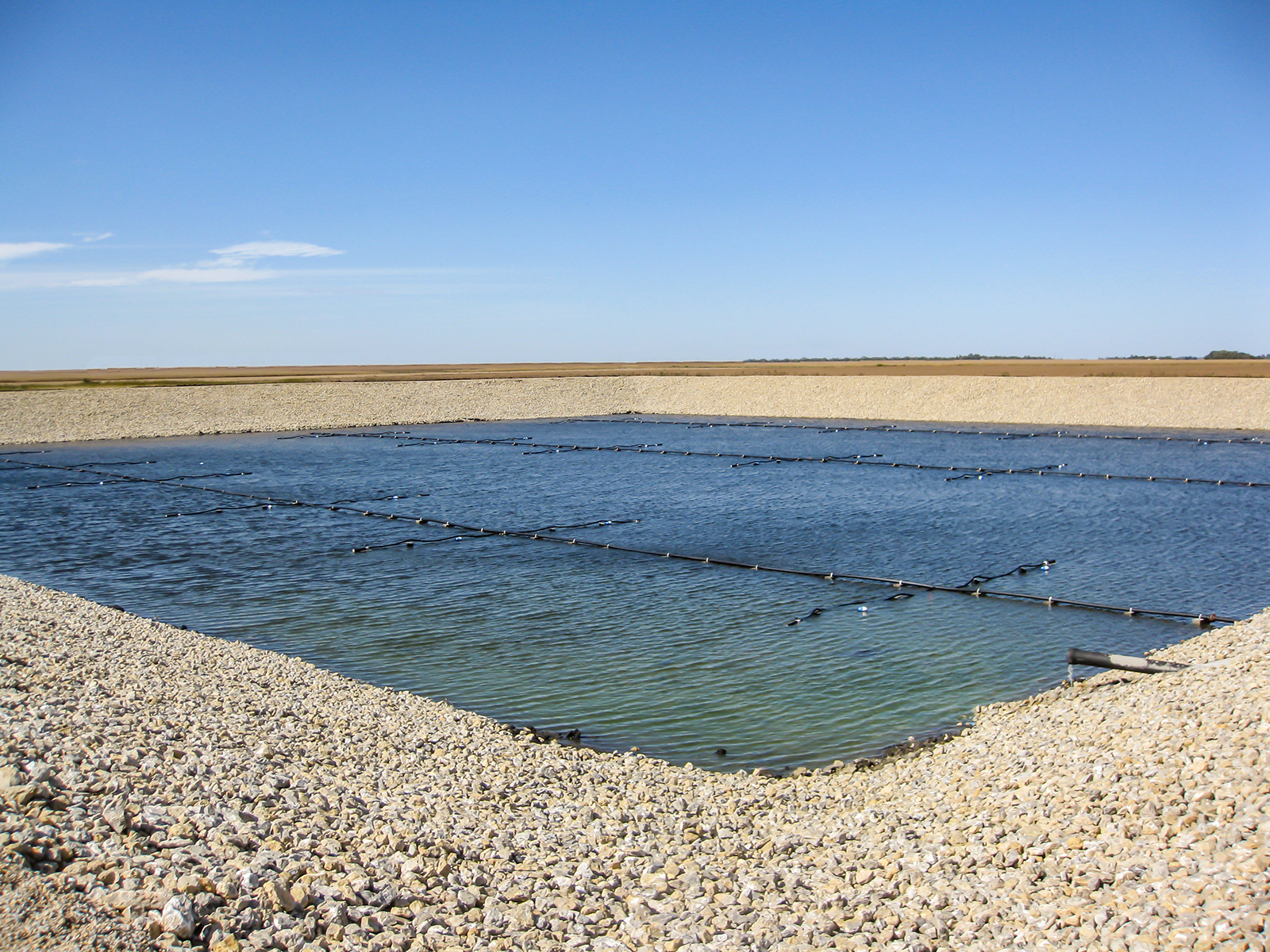

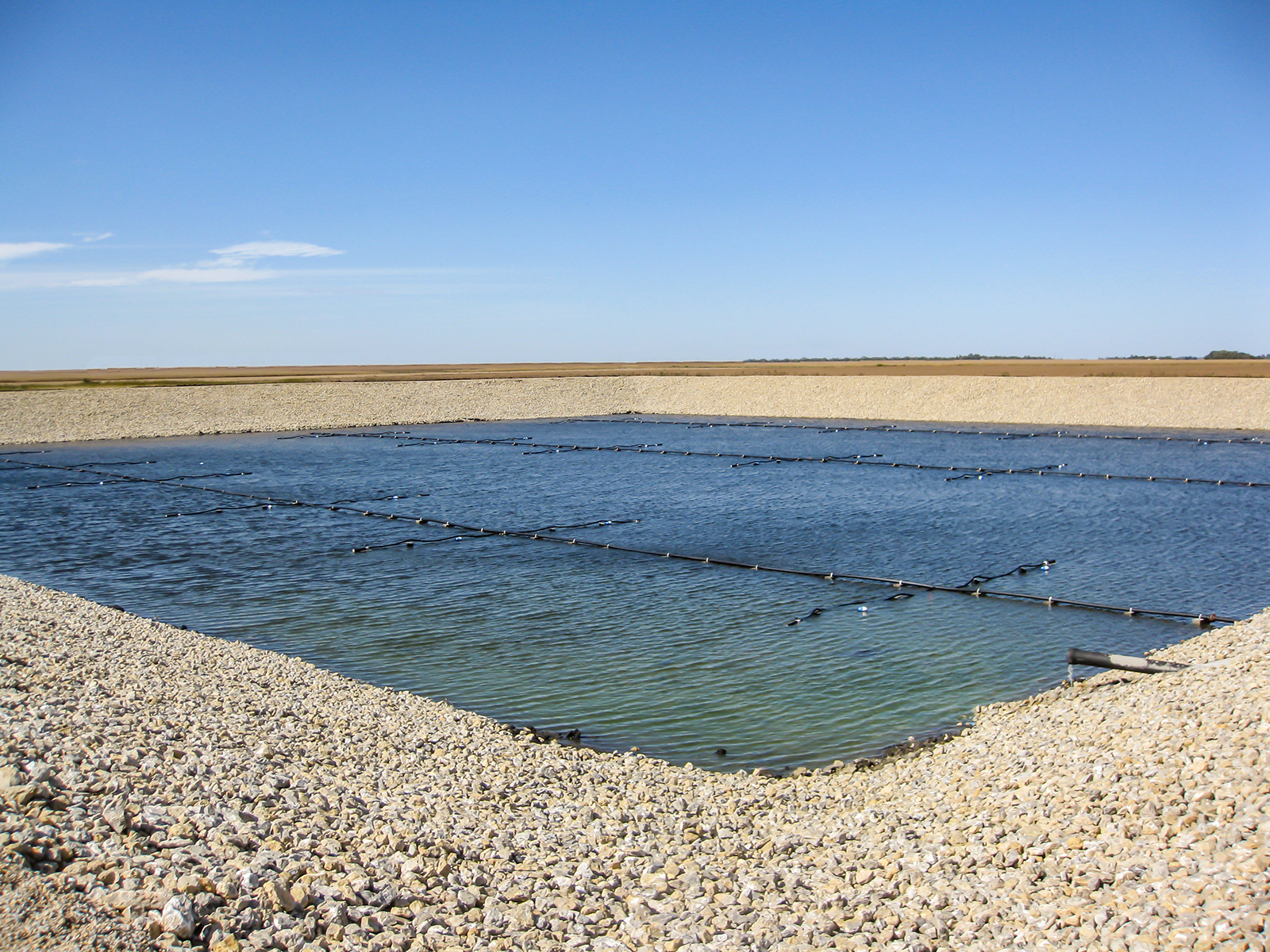

From wastewater ponds to zero liquid discharge (ZLD)! We can build custom solutions that provide the greatest water recovery possible whether adding on to an existing system or building an entire wastewater treatment plant.

How We Can Help With Your Commercial Wastewater Recycling

From wastewater ponds to zero liquid discharge (ZLD)! We can build custom solutions that provide the greatest water recovery possible whether adding on to an existing system or building an entire wastewater treatment plant.

How We Can Help With Your Commercial Wastewater Recycling

From wastewater ponds to zero liquid discharge (ZLD)! We can build custom solutions that provide the greatest water recovery possible whether adding on to an existing system or building an entire wastewater treatment plant.

Serving breweries, wineries, specialty food processors and specialized agriculture in Western North America by solving water scarcity issues.

- Our specialty is artisanal to commercial producers generating 2,500 –250,000 gal of wastewater a day

- We address high organic content (BOD) and elevated salt concentration.

Serving breweries, wineries, specialty food processors and specialized agriculture in Western North America by solving water scarcity issues.

- Our specialty is artisanal to commercial producers generating 2,500 –250,000 gal of wastewater a day

- We address high organic content (BOD) and elevated salt concentration.

Serving breweries, wineries, specialty food processors and specialized agriculture in Western North America by solving water scarcity issues.

- Our specialty is artisanal to commercial producers generating 2,500 –250,000 gal of wastewater a day

- We address high organic content (BOD) and elevated salt concentration.

We are Experts in cutting edge water recycling technologies

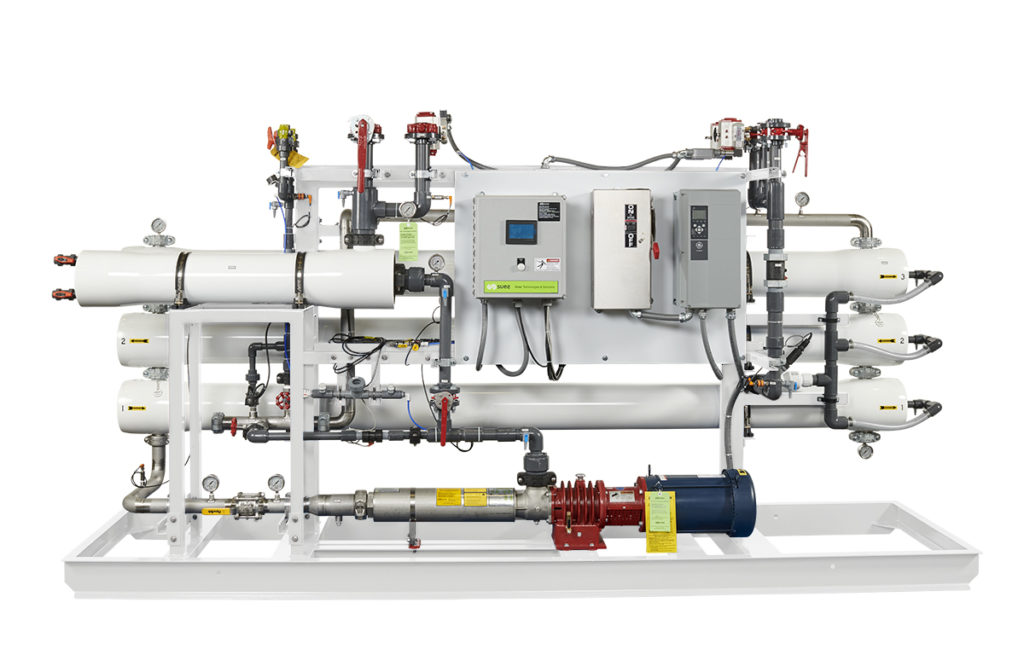

Backed by world-class membrane technology from Suez/Veolia along with an array of other suppliers, RWS finds the best filtration package to maximize your water recovery. We separate your wastewater components to meet water specifications for various water recycling opportunities. Our water recovery tools include:

We are Experts in cutting edge water recycling technologies

Backed by world-class membrane technology from Suez/Veolia along with an array of other suppliers, RWS finds the best filtration package to maximize your water recovery. We separate your wastewater components to meet water specifications for various water recycling opportunities. Our water recovery tools include:

Ultrafiltration (UF):

Removes 99% of TSS & BOD

Electrodialysis Reversal (EDR):

Nanofiltration (NF):

Ultrafiltration (UF):

Removes 99% of TSS & BOD

Electrodialysis Reversal (EDR):

Nanofiltration (NF):

Reverse Osmosis (RO):

NEW!

Osmotically Assisted Reverse Osmosis (OSRO):

Crystallizer:

Reverse Osmosis (RO):

NEW!

Osmotically Assisted Reverse Osmosis (OSRO):

Crystallizer:

Two typical configurations. Based on water characteristics, one of these flow schemes will maximize your water recover:

Alternative process flows may provide the best results. Let RWS review your wastewater today.

See how others have implemented these tools to maximize water recovery:

Two typical configurations. Based on water characteristics, one of these flow schemes will maximize your water recover:

Alternative process flows may provide the best results. Let RWS review your wastewater today.

See how others have implemented these tools to maximize water recovery:

Two typical configurations. Based on water characteristics, one of these flow schemes will maximize your water recover:

Alternative process flows may provide the best results. Let RWS review your wastewater today.

See how others have implemented these tools to maximize water recovery:

Details about Recovered Water Systems technologies:

Details about Recovered Water Systems technologies:

Ultrafilter (UF) & Membrane Bioreactor (MBR)

Ultrafiltration is the first step to recycling production wastewater. Through contact with plant material, the water can be high in total suspended solids (TSS) and organic material making it turbid and prone to biological growth. The measure of biological growth potential is measured as biological oxygen demand (BOD), the amount of oxygen microbes will require to break down the organic material. In order to utilize wastewater, the facility must minimize BOD and TSS.

BOD is reduced by the use of a digester. Microbes are intentionally fed the wastewater with sufficient oxygen to consume the organic material in a controlled environment. Adding a specialized ultrafilter designed to prevent fouling makes the digestor a membrane bioreactor (MBR), capable of reducing both BOD and TSS by 99%.

The MBR is a series of long, thin polymer tubes that are submerged in a digester. Water is drawn through the tubes by a pump, leaving the solid material behind. The outside of the tubes is in constant motion as a large volume of air is bubbled through the system to keep material from building up on the membranes. The MBR is constantly backflushed with clean water to remove any build up on the outside of the tubular membranes.

Photo copyright of Veolia; used with permission

Photo copyright of Veolia; used with permission

Ultrafilter (UF) & Membrane Bioreactor (MBR)

Ultrafiltration is the first step to recycling production wastewater. Through contact with plant material, the water can be high in total suspended solids (TSS) and organic material making it turbid and prone to biological growth. The measure of biological growth potential is measured as biological oxygen demand (BOD), the amount of oxygen microbes will require to break down the organic material. In order to utilize wastewater, the facility must minimize BOD and TSS.

BOD is reduced by the use of a digester. Microbes are intentionally fed the wastewater with sufficient oxygen to consume the organic material in a controlled environment. Adding a specialized ultrafilter designed to prevent fouling makes the digestor a membrane bioreactor (MBR), capable of reducing both BOD and TSS by 99%.

The MBR is a series of long, thin polymer tubes that are submerged in a digester. Water is drawn through the tubes by a pump, leaving the solid material behind. The outside of the tubes is in constant motion as a large volume of air is bubbled through the system to keep material from building up on the membranes. The MBR is constantly backflushed with clean water to remove any build up on the outside of the tubular membranes.

Photo copyright of Veolia; used with permission

Electrodialysis Reversal (EDR)

Electrodialysis (ED) is an electrochemical separation process where ions are transferred through selective ion-exchange membranes from one solution to another by means of a DC voltage.

As anions and cations in solution pass through their respective membrane, they concentrate in the ED reject solution, leaving the eluate low in salt and TDS and suitable for irrigation or further processing.

Electrodialysis Reversal (EDR) involves a combination of ED with cyclical reversal of DC polarity and fluid position. This is implemented to reduce the risk of significant scale build-up as the reversed current will help in pushing any formed scale back into solution.

In some cases, EDR is an ideal tool for water recycle. The product water is low in salts and can be readily reused for high value crop irrigation, cooling water tower make up or production facility wash water.

Photo copyright of Veolia; used with permission

Electrodialysis Reversal (EDR)

Electrodialysis (ED) is an electrochemical separation process where ions are transferred through selective ion-exchange membranes from one solution to another by means of a DC voltage.

As anions and cations in solution pass through their respective membrane, they concentrate in the ED reject solution, leaving the eluate low in salt and TDS and suitable for irrigation or further processing.

Electrodialysis Reversal (EDR) involves a combination of ED with cyclical reversal of DC polarity and fluid position. This is implemented to reduce the risk of significant scale build-up as the reversed current will help in pushing any formed scale back into solution.

In some cases, EDR is an ideal tool for water recycle. The product water is low in salts and can be readily reused for high value crop irrigation, cooling water tower make up or production facility wash water.

Nanofiltration (NF)

Nanofiltration processes MBR filtrate with membranes in the range of 250 molecular weight cut off (MWCO). The NF acts as a water softener, removing the ions that scale downstream equipment. These are the divalent ions of calcium and magnesium. While they cause scaling, they are also highly beneficial to plant growth. Blended with RO treated water, NF concentrate can deliver the ideal nutrient load to grapevines, landscaping or other high value vegetation.

Photo copyright of Veolia; used with permission

Photo copyright of Veolia; used with permission

Nanofiltration (NF)

Nanofiltration processes MBR filtrate with membranes in the range of 250 molecular weight cut off (MWCO). The NF acts as a water softener, removing the ions that scale downstream equipment. These are the divalent ions of calcium and magnesium. While they cause scaling, they are also highly beneficial to plant growth. Blended with RO treated water, NF concentrate can deliver the ideal nutrient load to grapevines, landscaping or other high value vegetation.

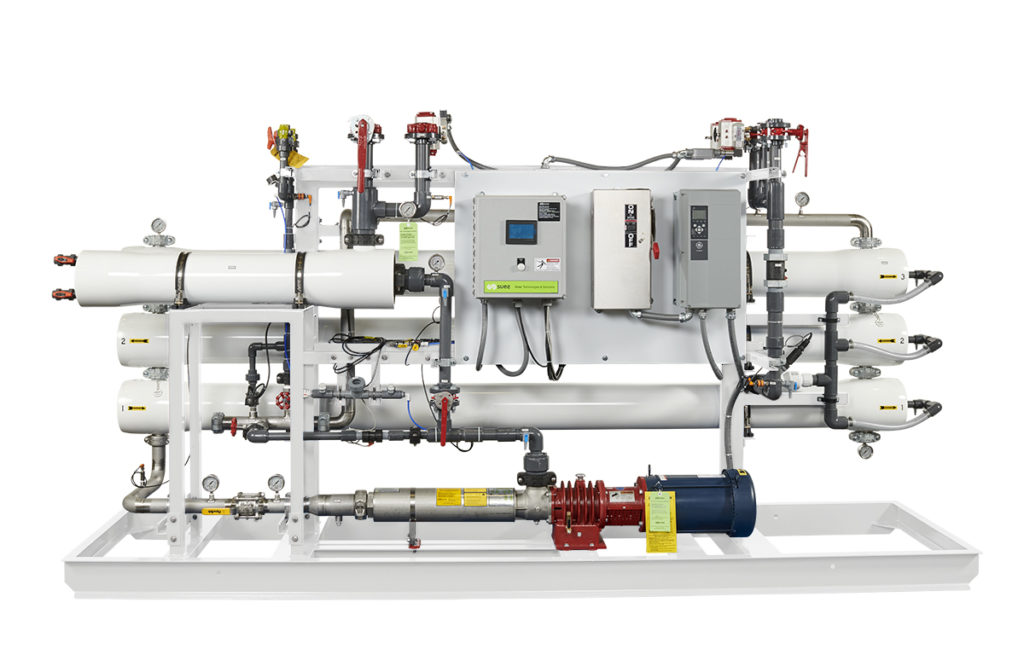

Reverse Osmosis (RO)

Reverse Osmosis (RO) further improves the quality of EDR eluate of NF permeate. RO utilizes membranes with a 100 MWCO and can effectively remove up to 99% of the incoming total dissolved solids (TDS). RO permeate can be recycled as water for cooling towers, boiler feed water, plant process water or even potable water. Depending on the composition of the original wastewater, the concentration from the RO can represent as little as 4% of the treated water volume. This concentrate stream can be further reduced in volume or hauled away for off-site disposal as the situation indicates.

Reverse Osmosis (RO)

Reverse Osmosis (RO) further improves the quality of EDR eluate of NF permeate. RO utilizes membranes with a 100 MWCO and can effectively remove up to 99% of the incoming total dissolved solids (TDS). RO permeate can be recycled as water for cooling towers, boiler feed water, plant process water or even potable water. Depending on the composition of the original wastewater, the concentration from the RO can represent as little as 4% of the treated water volume. This concentrate stream can be further reduced in volume or hauled away for off-site disposal as the situation indicates.

Osmotically Assisted Reverse Osmosis (OSRO)

The RWS Osmotically Assisted Reverse Osmosis (OSRO) brine concentrator can further recover water and minimize waste. While traditional reverse osmosis processes are limited to treating brines to an osmotic pressure below the membrane housing rated pressure, in OSRO, the osmotic pressure difference across a membrane is reduced by introducing a dilute brine to the permeate side of a hollow fiber membrane, allowing OSRO to increase permeate production, further reducing concentrate flow rate and increasing its salt concentration.

The OSRO can be integral to a zero liquid discharge (ZLD) operation. As with the RO, the permeate is very desirable process water and can be employed throughout the production facility. The concentrate is very high in dissolved solids, very close to the point where material precipitates out of solution. As such, the OSRO minimizes the capital requirements for a crystallizer or the expense of off-site disposal.

Osmotically Assisted Reverse Osmosis (OSRO)

The RWS Osmotically Assisted Reverse Osmosis (OSRO) brine concentrator can further recover water and minimize waste. While traditional reverse osmosis processes are limited to treating brines to an osmotic pressure below the membrane housing rated pressure, in OSRO, the osmotic pressure difference across a membrane is reduced by introducing a dilute brine to the permeate side of a hollow fiber membrane, allowing OSRO to increase permeate production, further reducing concentrate flow rate and increasing its salt concentration.

The OSRO can be integral to a zero liquid discharge (ZLD) operation. As with the RO, the permeate is very desirable process water and can be employed throughout the production facility. The concentrate is very high in dissolved solids, very close to the point where material precipitates out of solution. As such, the OSRO minimizes the capital requirements for a crystallizer or the expense of off-site disposal.

Photo copyright of Veolia; used with permission

Crystallizers

Crystallizers provide the final stage of water recovery and reduce waste to a small pile of salt components. RO/OSRO concentrate streams are prime candidates for crystallization. Using thermal energy, the salt material in the waste stream precipitates out of solution, allowing the solids to be repurposed or landfilled and the water to be recovered. This achieves zero liquid discharge!

Photo copyright of Veolia; used with permission

Crystallizers

Crystallizers provide the final stage of water recovery and reduce waste to a small pile of salt components. RO/OSRO concentrate streams are prime candidates for crystallization. Using thermal energy, the salt material in the waste stream precipitates out of solution, allowing the solids to be repurposed or landfilled and the water to be recovered. This achieves zero liquid discharge!

Contact Us Today For Your Water Recovery Solution!

We will work with you to determine which stages of filtration will create the ideal solution for your facility.

Contact Us Today For Your Water Recovery Solution!

We will work with you to determine which stages of filtration will create the ideal solution for your facility.

Contact Us Today For Your Water Recovery Solution!

We will work with you to determine which stages of filtration will create the ideal solution for your facility.